| |

|

Ballast Water Treatment Systems |

|

|

| TWO SYSTEMS – MULTIPLE SOLUTIONS – ONE WAY TREATEMENT |

| |

| 1. THROUGH FLOW ELECTROLYSIS-ELECTROCLEEN ™ (ECS) |

| |

|

| |

|

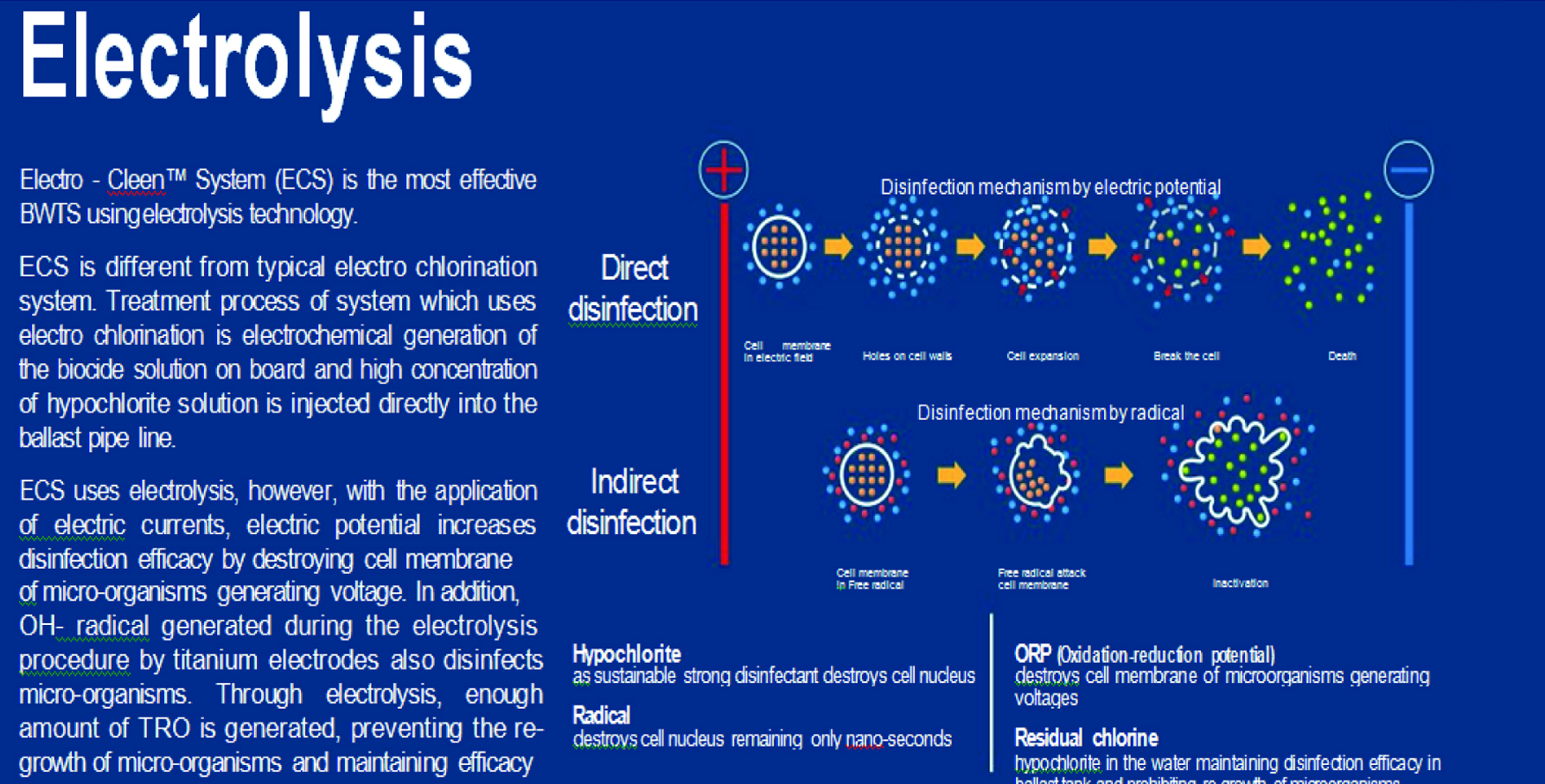

Techcross Electro-Cleen ™ System (ECS) is one of the most effective ballast water

management systems utilizing electrolysis. ECS treats all incoming ballast water by

in-situ production of hypochlorite with combined effects of electric shock and hydroxyl radical in

the Electro Chamber Unit (ECU). This simple disinfection processing is so powerful

that it destroys cell membrane of microorganisms and prevents re-growth, needing only

one-time treat-ment. It means ECS contributes to reduction in time and operating

cost. Techcross has upgraded ECS through continuous research and development involving

and approvals with Classification Societies and Flag States to better performance.

|

| |

|

|

|

|

|

|

IMO Final

Approval

2008 |

Korean

Government

2008 |

KR Type

Approval

2008 |

Liberian Flag

2011 |

ABS Type

Approval

2011 |

Japanese Flag

2012 |

| |

|

|

|

|

|

|

|

|

|

|

|

RS Type

Approval

2013 |

BV Type

Approval

2013 |

RINA Type

Approval

2013 |

Cyprus

2014 |

Lloyds Register

2015 |

Australia Flag

2016 |

| |

|

|

|

|

|

|

|

|

|

|

|

DNV&GL Design

Assessment

2016 |

CCS Type

Approval

2017 |

Danish

Government

2017 |

Greece Flag

2017 |

Panama Flag

2017 |

USCG T.A

2018 |

|

|

| ELECTRO-CLEEN ™ SYSTEM |

| |

|

|

-

ECU (Electro Chamber Unit)

-

TSU (TRO Sensor Unit)

-

PDE (Power Distributor Equipment)

|

-

ANU (Auto Neutralization Unit)

-

CPC (Control PC)

-

T-strainer

|

-

FMU (Flow Meter Unit)

-

CSU (Conductivity Sensor Unit)

-

FTS (Freshwater Temperature Sensor)

|

|

| Ballasting |

|

|

CSU |

|

FMU |

|

T-strainer |

|

ECU |

|

PDE |

|

TSU |

|

Ballast Tank

|

|

|

|

All the incoming ballast water passes through T-strainer before it is treated by ECU.

ECU can disinfect marine organisms in the ballast water with one time treatment during ballasting.

|

|

| Deballasting |

|

|

|

|

|

A main process during deballasting operation is neutralization of the treated water by ANU.

ANU is designed to automatically neutralize the treated water according to data about flow rate and TRO concentration by FMU & TSU.

|

| |

| Advantages of ECs |

| |

-

Strong disinfection efficacy

-

Low power consumption

-

Low operational costs

-

Largest reference list

-

Convenient installation and maintenance

-

Automation of system

-

Global network

|

|

SPECIFICATION OF ECS

|

|

|

Specific information of Electro-Cleen™ System |

| ECU (Electro Chamber Unit) |

| |

|

|

Specification |

ECU is the core component killing marine organisms in the ballast water ranging from ECU 150B to ECU 1000B. Each model can be

combined in parallel to achieve higher TRCs (Treatment Rated Capacity). |

|

Size |

ECU 150B |

W790 X D540 X H862 (mm), 390kg |

|

ECU 300B |

W1,243 X D763 X H862 (mm), 490kg |

|

ECU 450B |

W1,490 X D763 X H862 (mm), 660kg |

|

ECU 600B |

W1,840 X D763 X H862 (mm), 830kg |

|

ECU 1000B |

W2,000 X D1,124 X H914.5 (mm), 1,210kg

|

|

Power Supply |

AC 440V, 3ph, 60Hz (FROM PDE) |

|

Component

|

EM(Electro Module), PRU(Power Rectifier Unit), EPJ(ECU Power Junction box), ESJ(ECU Signal Junction box) |

|

Ex-Certificate

|

Ex II 2 G Ex de IIB T4 Gb : LCIE 12 ATEx 3095X / Ex de IIB T4 Gb : IECEx KGS 12.0008X |

|

|

|

|

|

|

|

< ECU 150B >

|

< ECU 300B >

|

< ECU 450B >

|

< ECU 600B >

|

< ECU 1000B >

|

|

|

| PDE (Power Distributor Equipment) |

| |

|

|

Specification |

PDE supplies AC 440V from the ship to all other components of ECS and controls communications of

all other components. |

|

Size |

PDE 12A |

W600 X D630 X H1,500 (mm), 175kg |

|

PDE 24A |

W700 X D700 X H1,900 (mm), 310kg |

|

PDE A4 |

W700 X D530 X H1,500 (mm), 250kg |

|

Power Supply

|

AC 440V, 3ph, 60Hz / AC220V, 60Hz |

|

|

|

|

|

< PDE 12A >

|

< PDE 24A >

|

< PDE A4 >

|

< ANU 5T >

|

< ANU 10T >

|

|

|

| ANU (Auto Neutralization Unit) |

| |

|

|

Specification |

ANU is designed to automatically neutralize treated ballast water prior to its discharge so that the discharge of

Residual Biocides may not exceed 0.1ppm (instantaneous maximum limit) according to TRO level measured by TSU.

|

|

Size |

ANU 5T |

W800 X D733 X H1,655 (mm), 220kg |

|

ANU 10T |

W1,200 X D733 X H1,655 (mm), 308kg |

|

Power Supply

|

AC 220V, 60Hz (FROM PDE) |

|

Neutralizer

|

Sodium Thiosulfate |

|

Mixture Ratio

|

2 (Fresh water) : 1 (Neutralizing agent) |

|

Tank Capacity |

ANU 5T |

100 Liter for each tank (Both : 200 Liter) |

|

ANU 10T |

200 Liter for each tank (Both : 400 Liter) |

|

|

|

|

|

|

TSU (TRO

Sensor Unit) |

|

Specification |

TSU measures

concentrations of TRO (Total

Residual Oxidant) generated by ECU

during ballasting operation. TSU

also checks the TRO level in the

treated ballast water for proper

neutralization of ballast

water before its discharge. |

|

Size |

W470 X D450 X

H1,347 (mm), 100kg |

|

Power Supply

|

AC 220V, 60Hz

(FROM PDE) |

|

Ex-Certificate |

II 2 G Ex px

IIC T4 Gb / ITS11 ATEx 17384 |

|

|

|

|

|

|

|

CPC (Control PC &

S/W) |

|

Specification |

Control PC features an

upgraded touchscreen interface which is easy

& simple to operate ECS. In addition, the

CPC shows all the data saved relating to ECS

operation. |

|

Size |

W480 X D119 X H660

(mm), 35kg |

|

Power Supply

|

AC 220V, 60Hz (FROM PDE) |

|

|

|

|

|

|

T-strainer |

|

Specification |

T-strainer with a 3mm

mesh filter is used during ballasting

operations to filter out large marine

species and foreign materials in the

incoming ballast water. It helps protect

electrodes inside the

ECU to maintain an optimal performance of

ECU for a strong disinfection efficacy. |

|

Size |

W550 X D366 X H503

(mm), 87kg |

|

Type |

Straight, Angle |

|

Pressure Range |

-1 ~ 10 Bar |

|

|

|

|

|

|

FMU (Flow Meter

Unit) |

|

Specification |

Measures flow rate of

ballast water during ballasting and

deballasting operation. |

|

Power Supply

|

AC 220V |

|

|

|

|

|

|

FTS (Freshwater

Temperature Sensor) |

|

Specification |

Measures temperature of

cooling water supplied to a rectifier from

vessel. |

|

Power Supply

|

DC 24V |

|

|

|

|

|

|

CSU (Conductivity

Sensor Unit) |

|

Specification |

Measures electrical

conductivity of seawater passing through ECU

during ballasting operation. |

|

Power Supply

|

DC 24V |

|

|

|

|

|

|

GDS (Gas Detection

Sensor) |

|

Specification |

Detects a possible leak

of hydrogen gas from ECU. |

|

Power Supply

|

DC 24V |

|

|

|

|

|

|

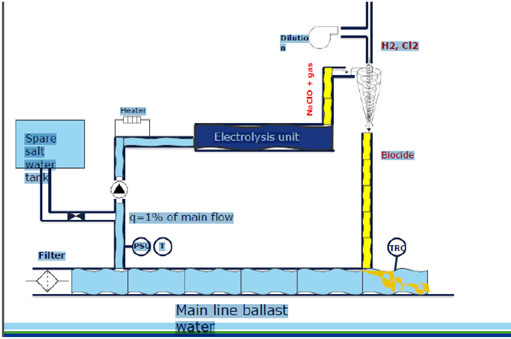

2. Electro-Chlorination Technology – Slip Stream Method

Disinfection principle——Core technology

When seawater flows through the

electrolyzer, decomposition reactions take place on

the electrode surfaces, with chlorine produced at

the anode and hydrogen gas at the cathode. Chlorine

gas can be dissolved in water to produce

hypochlorous acid and hydrochloric acid rapidly:

|

Cl2 + H2O → HOCl + Cl- + H+

So the whole reaction is:

NaCl + H2O → NaOCl + H2↑

Sodium hypochlorite solution as a very effective

germicide can be kept in ballast water for a certain

period to effectively kill the plankton, spores,

larvae and pathogens contained in the ballast water.

|

ECS-HYCHLORTM

SYSTEM

TECHCROSS HYCHLOR ELECTROCHLORINATION – SIDE STREAM

DOSING SYSTEM

The

ECS-HYCHLORTM System adopts a disinfection technology combining

filtration with indirect eletrolysis. It consists of filtration, electro

chlorination unit and neutralization units with some of accessories.

The filter unit is mounted directly on the main ballast pipeline to eliminate

larger microorganisms and suspended solid than 50㎛

in size. The organisms and solids are filtered out by filtration unit and

discharged along with ambient water, using auto back-flushing function. During

de-ballasting, ballast water does not pass through the filtration unit.

The indirect electro chlorination unit operates only during ballasting to

disinfect microorganisms filtered out at first by the filtration unit. Only 1%

of total ballast water flows to the electro chlorination unit to be used to

generate the highly concentrated TRO. This concentrated TRO is injected to the

main ballast line to be mixed with the rest of ballast water and maintain

maximum TRO concentraion of 5.0mg/L.

The neutralization unit neutralizes the residual TRO by using sodium thiosulfate

as the neutralizing agent before discharging the treated water overboard during

de-ballasting. The maximum allowable discharge concentration of TRO is 0.1mg/L.

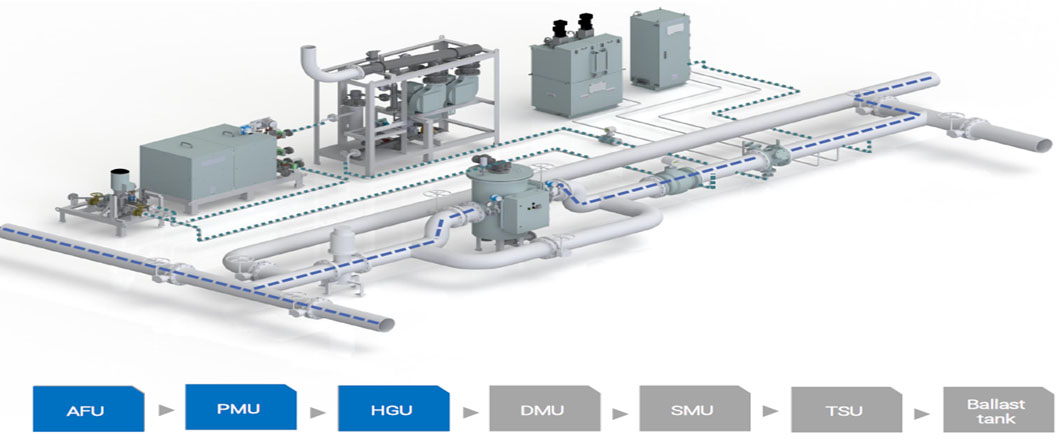

F:LOW DIAGRAM - BALLASTING

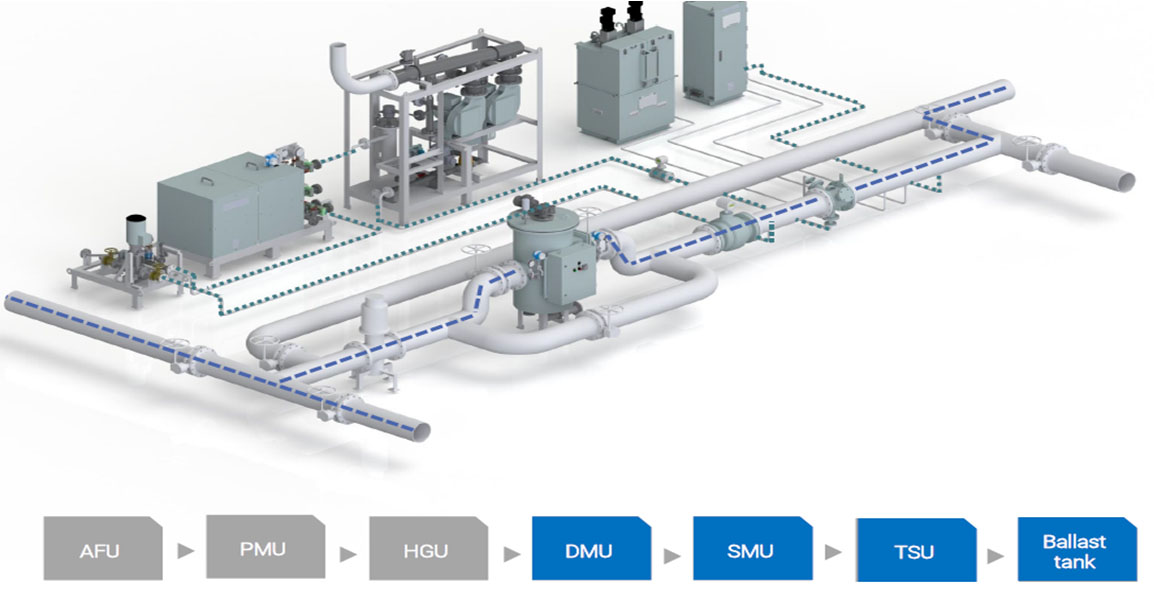

F:LOW DIAGRAM - DEBALLASTING

|

|

Main Equipment |

AFU (Auto Filter Unit)

Removes particles >50㎛ during ballasting.

The head loss by the unit is below 0.1 bar

and negligible |

|

HGU (Hypochlorite Generation Unit) Main

Equipment – Electrochlorination

HGU is indirect electrolysis component in

the form of side stream. It generates

oxidants by electro chlorination and

disinfects microorganisms filtered out by

AFU. |

| |

|

|

DMU (Degas Module Unit)

Dilutes and discharges H2 gas, which is

generated during electrolysis, by an air

vent valve and a blower. It is composed of

safe components which are approved the

explosion-proof certification.

|

|

SMU (Static Mixer Unit)

Injects high concentrated TRO to the main

ballast pipeline for the dilution by side

stream method during ballasting and injects

neutralizing agent during de-ballasting. |

|

|

Supporting Equipmen |

PMU (Pump Module Unit)

Delivers 1% of sea water to the Electrode

Module through main ballast pipeline by the

pump. It is composed of a pump, an auto

control valve and a flow meter. |

|

ANU (Auto Neutralization Unit)

Before discharging the treated water

overboard, ANU doses neutralizing agent to

maintain TRO concentration with below

0.1mg/L during de-ballasting only. |

| |

|

|

TSU (TRO Sensor Unit)

Measures TRO concentration during ballasting

and de-ballasting. TSU is controled by HMI.

|

|

Sensors - FMU (Flow Meter Unit)

Measures flow rate of ballast water during

ballasting and de-ballasting. |

| |

|

|

Sensors - CSU (Conductivity Sensor Unit)

Measures electrical conductivity of seawater

during ballasting operation |

|

Others - Local Control Unit

|

| |

|

|

|

| |

|

INSTALLATION REFERENCES |

Case 01 [New building

: SKID mount type]

|

| |

|

Specification |

|

|

|

|

Division |

Specification |

Division |

Specification |

|

Ship type |

170K LNG |

Model |

ECS 2600B X 2sets |

|

Class |

DNV |

Installation location |

E/R |

|

Capacity |

5200㎥/h X 1set |

Date |

2013 |

|

|

|

|

|

|

| |

Case 02 [New building

: On-deck room]

|

| |

|

Specification |

|

|

|

|

Division |

Specification |

Division |

Specification |

|

Ship type |

37K PC Tanker |

Model |

Ex-ECS 750B X 2sets |

|

Class |

KR |

Installation location |

On-deck |

|

Capacity |

750㎥/h X 2sets |

Date |

2014 |

|

|

|

|

|

|

| |

|

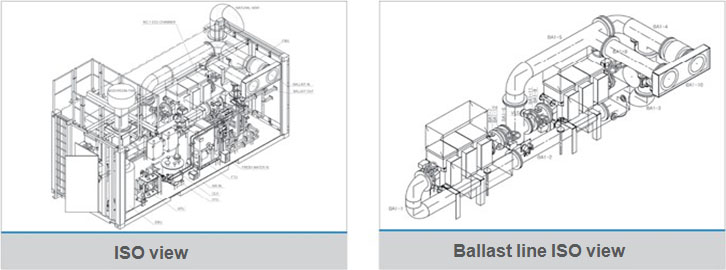

Case

03 [New building & Retrofit : Container SKID] |

|

|

Specification |

|

|

Division |

Specification |

|

Ship type |

Tanker |

|

Container

size |

20ft |

|

Model |

Ex-ECS 900B

X 1set |

|

Installation location |

On-deck |

|

|

|

|

|

| |

|

|

|

| |

|

|

|

|